Introduction

Suppressors generate significant heat during sustained fire, posing a serious risk of burns to personnel and equipment. Additionally, excessive heat can cause optical mirage distortion and contribute to premature wear on suppressors and surrounding gear. Traditional suppressor covers often exacerbate these issues by trapping heat. MODTAC Suppressor Shields offer an innovative solution by incorporating advanced materials and an innovative free-floating design to mitigate these problems effectively.

How MODTAC Suppressor Shields Work

MODTAC Suppressor Shields, advanced suppressor covers, leverage a unique combination of high-performance materials and an optimized design to enhance suppressor safety and effectiveness. Suppressor Shields are engineered with an attaching mechanism to “free-float” the Shield over the suppressor creating an air gap around the suppressor. This gap serves as a highly effective insulator, reducing extreme temperatures before they reach the advanced composite Shield. The composite Shield provides exceptional thermal resistance due low thermal conductivity which minimizes heat transfer to the outer Shield surface. MODTAC Suppressor Shields effectively leverage the two insulating layers to create a unique, high-performance thermal barrier that results in the following benefits:

Burn Prevention: By limiting direct heat transfer from the suppressor to the Shield’s surface, external temperatures remain significantly lower, reducing the risk of accidental burns.

Burn Prevention: By limiting direct heat transfer from the suppressor to the Shield’s surface, external temperatures remain significantly lower, reducing the risk of accidental burns. Passive Cooling: The uninhibited airflow around the suppressor allows it to cool naturally, as if the Suppressor Shield were not present, maintaining efficient heat dissipation without trapping thermal energy.

Passive Cooling: The uninhibited airflow around the suppressor allows it to cool naturally, as if the Suppressor Shield were not present, maintaining efficient heat dissipation without trapping thermal energy. Thermal Signature Reduction: Shield outer surface temperatures, during a moderate weapon system firing schedule, generally operate in temperature zones that are indistinguishable from surrounding environmental temperatures by many thermal detection systems.

Thermal Signature Reduction: Shield outer surface temperatures, during a moderate weapon system firing schedule, generally operate in temperature zones that are indistinguishable from surrounding environmental temperatures by many thermal detection systems.

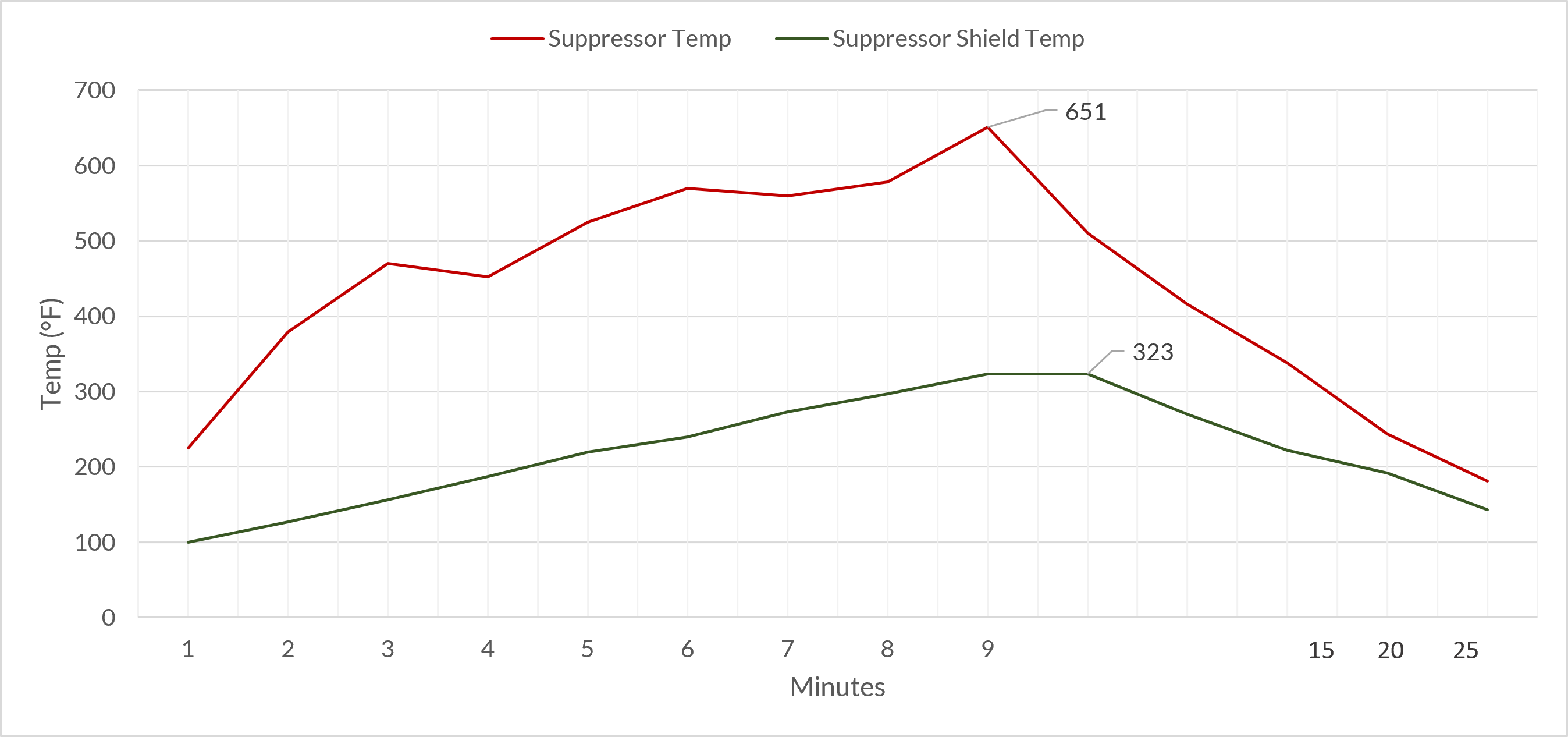

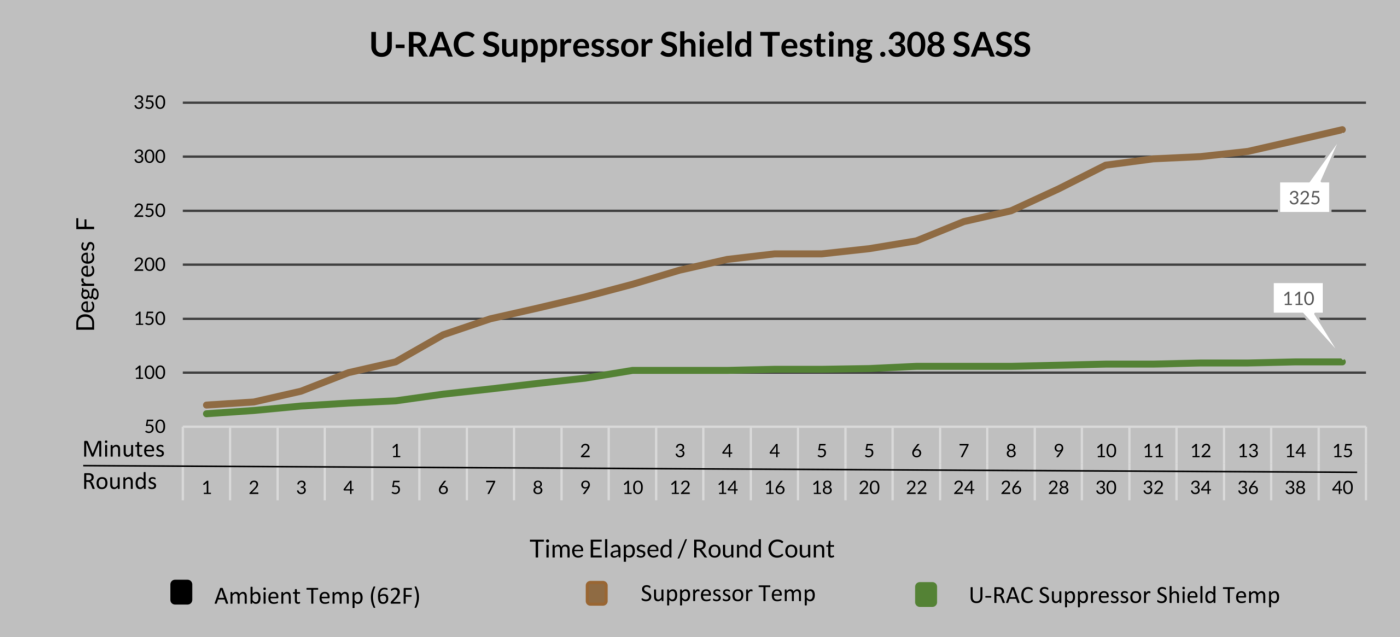

Independent third-party testing has demonstrated the superior thermal performance of MODTAC Suppressor Shields:

Sustained high temperatures can significantly impact the effective lifespan of a suppressor. Excessive heat exposure contributes to several key degradation factors:

By allowing natural cooling and preventing additional heat buildup, MODTAC Suppressor Shields help mitigate these risks, supporting both performance and longevity of the suppressor without introducing additional thermal stress.

The MODTAC Suppressor Shields deliver multiple operational advantages:

MODTAC Suppressor Shields set the standard in suppressor heat management, improving operational safety, enabling the mission, and protecting gear. With proven testing data supporting their effectiveness, the Suppressor Shield provides a critical enhancement for professionals seeking safe, effective suppressor performance.